Plastique PVC pour coffrage à béton

| Marque déposée/Identifiant: | JINGFANG® Plastique PVC pour coffrage à béton usine chinoise |

| Matière première: | UPVC (également appelé PVC plastique-acier) |

| Largeur: | jusqu'à 1300 mm disponible |

| Longueur: | aucune limite, peut être personnalisé |

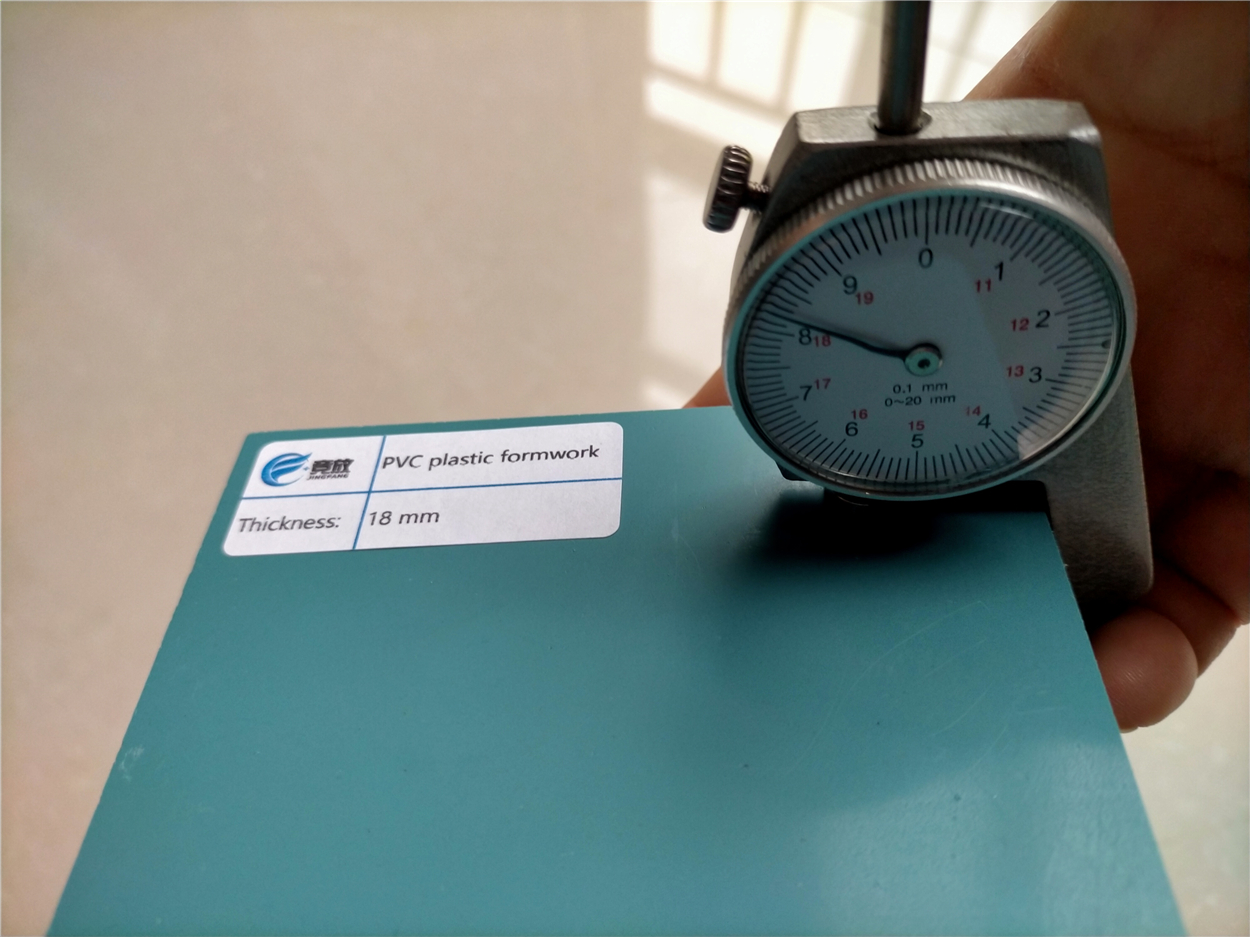

| Épaisseur: | 6 – 21 mm disponibles |

| Densité: | 0,70 g/cm³ ± 0,5 % (standard), personnalisable 0,60 – 0,90 g/cm³ |

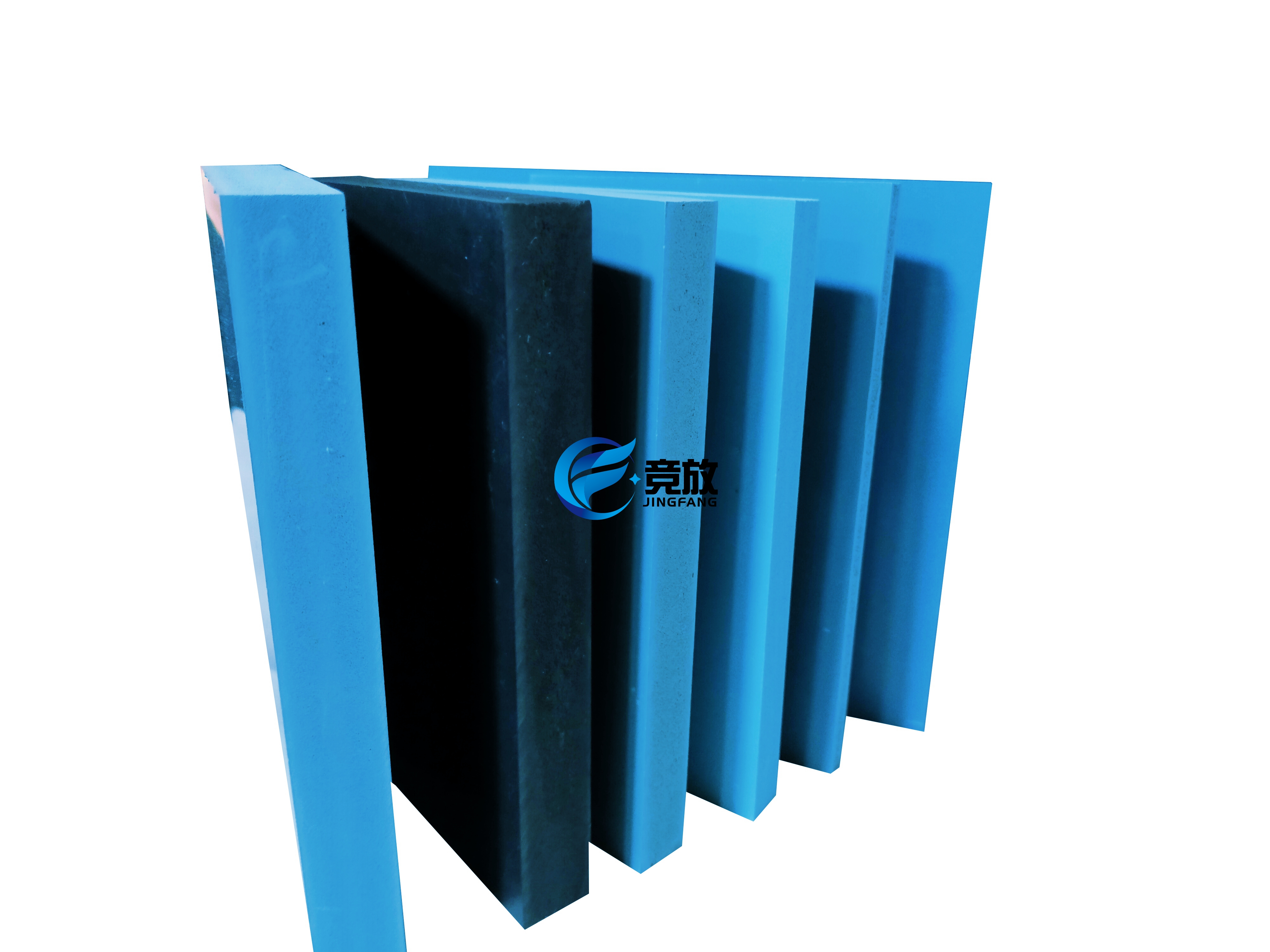

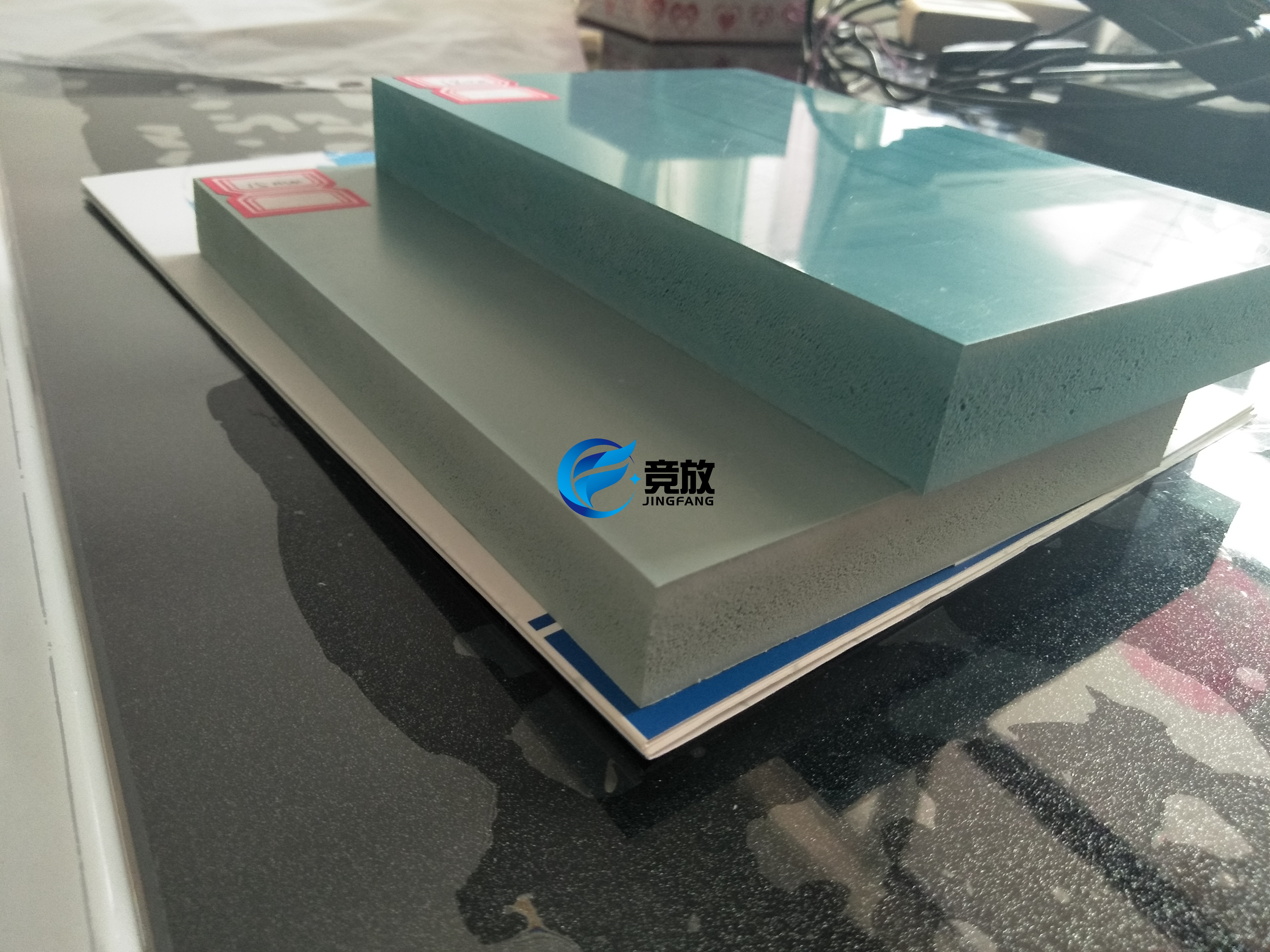

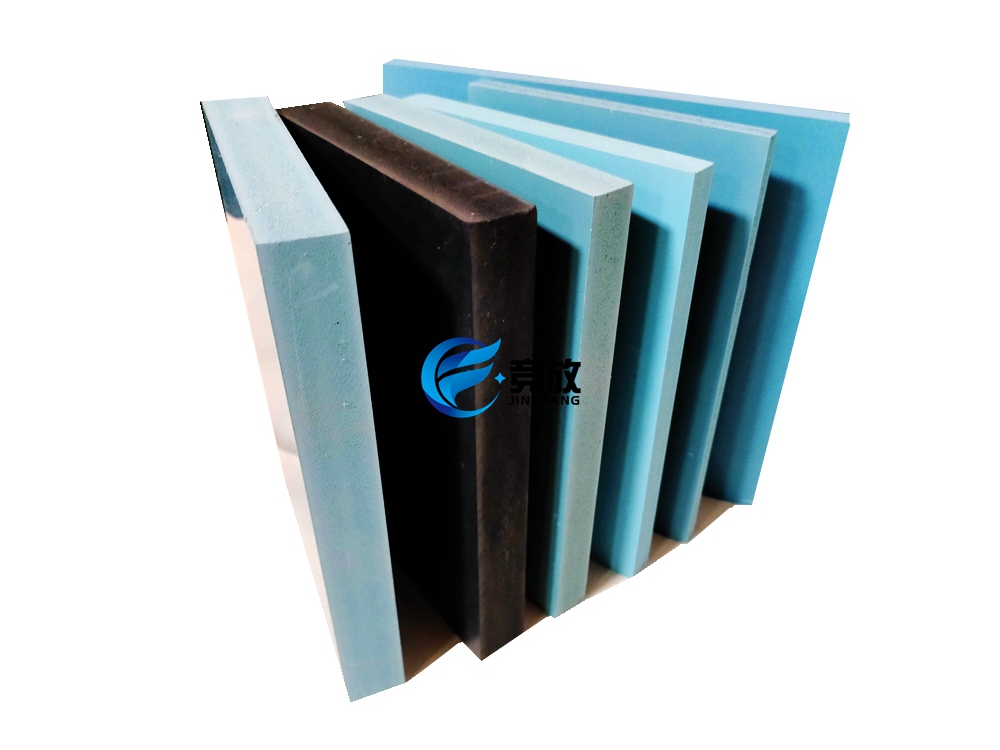

| Couleur: | Vert Turquoise / Bleu Azur, autres personnalisables |

| Chargement et emballage: | en vrac ou avec des palettes |

| Port FOB: | Qingdao, Lianyungang, Tianjin, Shanghai, etc. |

| Transport d'exportation: | FCL/LCL par mer, route ou chemin de fer |

What is PVC plastic for concrete formwork?

Definition: what is reuse 50+ times PVC plastic for concrete formwork ?

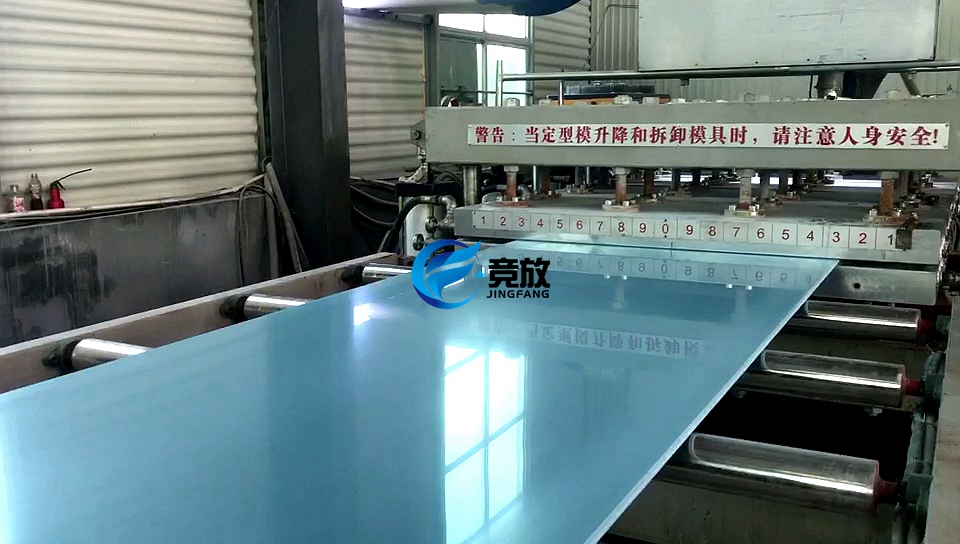

PVC plastic for concrete formwork is a new type of plastic formwork, which is made of PVC raw material only.

It has same sizes and applications with plywood formwork, but much better performance. In Chinese and Asia simple wooden structure, it can be reused at least 50 times. With premium structure which provided good protection to PVC plastic for concrete formwork panels, it can be reused much more times.

With its development, we can save much a lot of forest resources. So its development is in accordance with the world trend of energy conservation and environmental protection.

Energy-saving with its environmental protection, and economic with its cyclic regeneration. PVC plastic for concrete formwork is gradually replacing the traditional plastic shuttering formworks in the civil engineering.

Sizes and thickness

PVC plastic for concrete formwork has the same sizes and applications as plywood formwork:

Width: up to 1220mm

Length: up to 4200+mm

Thickness: up to 22mm

The most popular sizes are same as plywood formwork: 1220*2440*12mm/15mm/18mm. Special sizes can be cut or customized.

Characteristics and advantages

1. Reuse 50+ times, saving much cost

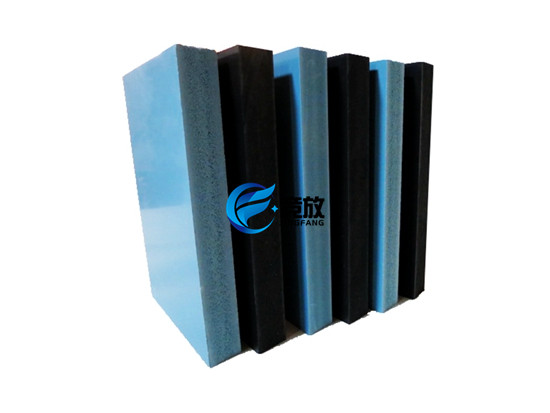

PVC plastic for concrete formwork can be reused ≥ 50 times in plain wooden structures (left photo), and much more times in premium metal structures (right photo). This means the lifespan of 1 piece of PVC plastic for concrete formwork equals to ≥ 5 ~ 10 pieces of plywood formwork.

2. Same sizes & applications as plywood formwork

PVC plastic for concrete formwork comes with the same sizes and applications as conventional plywood formwork, including for wall, slab, column, stairs, tunnel, bridge, etc.

Its usage in preparing, handling, installation and assembly are same as using plywood formwork.

No changes to the formwork structure and construction process.

3. No Special Tools and Learning Curve

PVC plastic for concrete formwork has excellent screw holding strength, can be freely saw, cut, drill, nail, and shaped into any sizes as desired.

Workers may prepare the PVC plastic for concrete formwork as the same way that they use conventional plywood formwork.

No additional training or special tools required for workers to handle the product.

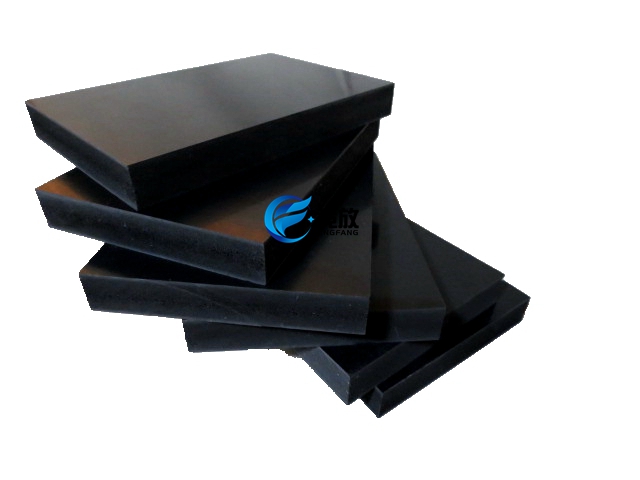

4. Never Delaminates

PVC plastic for concrete formwork adopts the foaming technology, not layerinng or laminating. It will never delaminate even after reusing 50+ times.

So it can be reused continually unless it is badly cracked by violent construction (such as throwing hardly frequently)

5. Smooth Concrete Surface

Our mirror surface technology ensures PVC plastic for concrete formwork smooth surface, and is able to maintain its smoothness even after reusing for 50+ times. This helps ensuring all the wall surface in uniform smoothness across first to top floor.

6. High Load-Bearing Capacity

Our PVC plastic for concrete formwork has good surface hardness with excellent strength in during high impact. This is another important reason why it can be reused 50+ times in a plain wood support structure.

7. High Bending Strength and Elasticity

Our PVC plastic for concrete formwork has excellent bending strength. You can curve it freely in your round formwork structure.

Even during winter season, our PVC panel maintains its elasticity in bending. Non-fragile.

8. Antiflaming

With special formula and technology, our PVC plastic for concrete formwork is anti-flaming. This effectively reduces the fire risk and limits the spread of fire.

If using plywood formwork, workers need to implement more additional fire precautions and protection measurements at site.

9. Weatherproof Against Harsh Environment, UV resistant, Chemical Resistant

Our PVC plastic for concrete formwork is 100% waterproof, UV resistant, chemical/acid/alkali resistant.

So it is durable enough to be used, stored or placed at outdoor environment without the need of any protection, including under the weather of raining, snowy, in Summer, or in Winter.

10. High Temperature Resistant and Freezing-thawing Resistant

Our PVC plastic for concrete formwork has good resistance against temperature.

It shows no shrinkage, bulge, cracking or any sign of deformation under -40℃ to +75℃. Actually, it can hold 200+℃, which is the temperature of the manufacturing process.

Non-fragile in Winter. You can put it outside without special curing in snowy weather. We have customers in South Asia and Middle East countries, where it can work well under high temperature.

11. No Need Releasing Oil, Easily Releasing and Cleaning

With sustaining smooth surface and excellent hardness, PVC plastic for concrete formwork doesn't stick concrete stubbornly, which ensures it to be easily leaned with water+mop.

No releasing agent or oil is required before and during concrete demoulding process. Easily cleaning.

Easily demoulded by hands, leaving the wall surface smooth and glossy without the need of secondary plastering.

12. Recyclable with Extra Returns

PVC is one of the most popular plastic materials in the world. It is easy to resell used PVC plastic for concrete formwork to related plastic industries, with higher returns than used plywood formwork. Such as PVC tubes, plastic furniture, cabinet, box, etc.

For full sizes, you can reuse them continually or rent out to other projects;

For small parts, you can can re-sell them to related industries.

13. Environment friendly

Our PVC plastic for concrete formwork is made of PVC material only, never add any wood powder or calcium powder. It adopts foaming technology, not layer ot laminated, no any glue is used in manufacturing. So it is environment friendly, doesn't discharge any infectant or toxic gas. It is in accordance with environmental trend of the earth.